Discussion on High Pressure Common Rail Technology of Diesel Engine

Brief Introduction of 1. High Pressure Common Rail Technology

Let's first understand the limitations of the traditional diesel engine fuel injection system:

The

working process of the traditional diesel engine fuel injection system

is: after the diesel oil is increased by the high-pressure fuel pump, it

is injected into the cylinder combustion chamber through the fuel

injector according to a certain fuel supply timing and fuel supply. In

the fuel injection process, due to pressure fluctuations, there is a

secondary injection phenomenon. Since the secondary fuel injection

cannot be completely burned, the smoke and hydrocarbon emissions are

increased, and fuel consumption is also increased. In addition, the

residual pressure in the high-pressure oil pipe will change after each

injection cycle, which will cause unstable injection, especially in the

low-speed area. In severe cases, not only the fuel injection is uneven,

but also intermittent non-injection will occur. phenomenon.

With the

development and progress of engine automatic control technology, in

order to solve the fuel injection combustion defects caused by the

change of diesel fuel pressure, modern diesel engines adopt a

high-pressure common rail electronically controlled fuel injection

technology, so that the performance of diesel engines has been

comprehensively improved.

After mechanical injection, supercharged

injection and ordinary electronic injection, common rail high-pressure

injection has appeared in diesel engines in recent years. High-pressure

common rail (Common Rail) electronic injection technology refers to the

closed-loop system composed of high-pressure fuel pump, pressure sensor

and electronic control unit (ECU). Compared with the general fuel

injection system, its pressure establishment, injection pressure control

and injection The fuel injection process is independent of each other

and can be flexibly controlled. It uses a high-pressure fuel pump to

deliver high-pressure fuel to the public fuel supply pipe (Rail), and

realizes precise control through the oil pressure in the public fuel

supply pipe, so that the pressure of the high-pressure fuel pipe

(Pressure) has nothing to do with the engine speed, which can greatly

reduce the diesel engine The degree to which the fuel supply pressure

changes with the engine speed.

In addition, the high-precision parts

of the common rail fuel injection system have high surface processing

quality requirements, high geometric accuracy, and many special

requirements. The processing is micron and sub-nanometer precision,

which represents the highest processing level in the current machinery

manufacturing industry.

Composition and working principle of 2. high pressure common rail system

2.1. Composition of high pressure common rail injection system

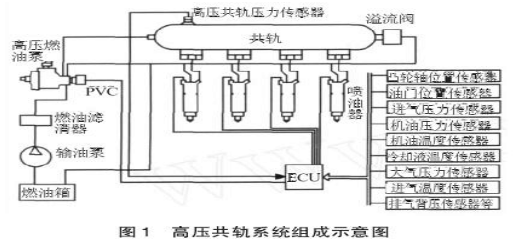

The high-pressure common rail injection system is mainly composed of

high-pressure fuel pump, common rail pipe, electronic control injector,

various sensors and electronic control unit ECU, as shown in Figure 1.

When the engine is working, the gear pump on the high-pressure oil pump

sucks oil from the fuel tank through negative pressure, and sends the

filtered fuel to the high-pressure oil pump at a certain pressure (about

5 ~ 7bar). The fuel enters the high-pressure plunger cavity and is

compressed, and enters the common rail pipe through the high-pressure

fuel pipe to form high pressure. Each cylinder injector is connected to

the common rail pipe through the high-pressure fuel pipe to achieve

high-pressure injection.

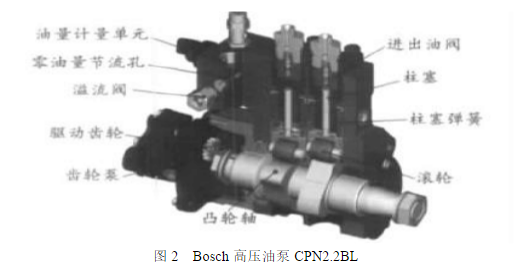

2.1.1 High pressure pump

The

high-pressure fuel pump is one of the key components in the

high-pressure common rail system. Its main function is to pressurize

low-pressure fuel into high-pressure fuel, which is stored in the fuel

rail and waits for the injection command of the ECU. The high-pressure

oil pump is composed of a gear pump, a fuel metering unit, an overflow

valve, an inlet and outlet valve, and a high-pressure plunger. Take

CPN2.2BL, which Bosch is currently widely used in the Chinese commercial

vehicle market and has begun localized production, as an example. Its

structure is shown in Figure 2 [12].

The design criteria for the fuel supply of high-pressure oil pumps are:

The high-pressure oil pump must be guaranteed throughout its life and under any operating conditions.

The fuel supply can meet the fuel injection requirements of the engine under a certain rail pressure, that is, the fuel balance.

CPN2.2BL

uses 2 in-line plunger design, driven by the engine camshaft, the

transmission ratio is 1:2, similar to the traditional mechanical pump,

in order to facilitate the Euro II engine upgrade. The lubrication

method is oil lubrication, and the lubricating oil circuit is directly

connected with the engine lubricating oil circuit. The task of the gear

pump is to supply enough low-pressure fuel to the high-pressure fuel

pump. It is installed at the rear end of the high-pressure fuel pump

body and driven by a gear located at the end of the high-pressure fuel

pump camshaft. Its speed is 2.85 times that of the high-pressure fuel

pump. When the fuel enters the high-pressure part, it enters the

high-pressure plunger cavity through the fuel metering unit, and enters

the fuel rail after being compressed. At the same time, the excess fuel

returns to the fuel tank through the overflow valve. The main function

of the fuel metering unit is to adjust the amount of fuel entering the

high-pressure plunger cavity to control the fuel pressure in the common

rail pipe.

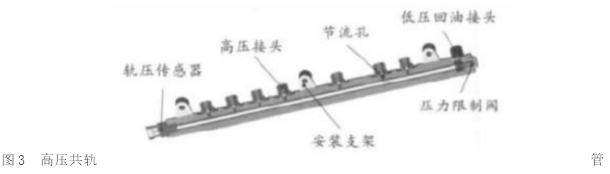

2.1.2 High Pressure Common Rail

The common rail pipe is

a unique component in the electronically controlled high-pressure

common rail system, which mainly includes high-pressure joints,

orifices, rail pressure sensors and pressure limiting valves, as shown

in Figure 3. The main function of the common rail pipe is to accumulate

pressure and distribute fuel, dampen fuel pressure fluctuations, and

limit the maximum fuel pressure so that it does not exceed the safety

limit. The rail pressure sensor provides the real-time pressure signal

in the common rail pipe to the ECU as an input for the closed-loop

control of the rail pressure. The orifice design at the inlet and outlet

of the fuel rail can reduce the pressure fluctuation in the common rail

pipe and the high pressure oil pipe.

The pressure limiting valve is a

mechanical valve that opens when the pressure exceeds a certain limit

to ensure that the common rail pipe releases the pressure quickly when

the pressure is abnormal to ensure system safety. When the pressure

limit valve is opened, it can still maintain the rail pressure in a

normal range (such as 700 ~ 800Bar), so that the vehicle can continue to

run to the maintenance station in case of failure, that is, limp home.

2.1.3 Injector (Injector)

The fuel injector is the most critical

and complex component in the electronically controlled high-pressure

common rail system. Its function is to control the opening and closing

of the solenoid valve according to the electrical signal sent by the

ECU, and to inject the fuel in the high-pressure fuel rail with the best

injection Time, fuel injection volume and fuel injection rate are

injected into the combustion chamber of the diesel engine. The fuel

injector is mainly composed of fuel injector body, solenoid valve, fuel

nozzle, needle valve assembly and spring. Figure 4 shows Bosch's

second-generation commercial vehicle fuel injector CRIN2. When the

solenoid valve is not energized, the armature presses the ball valve

tightly on the valve seat. At this time, the pressure in the control

chamber and the pressure chamber are balanced. The nozzle needle valve

is tightly pressed on the nozzle seat surface by the spring preload

force and does not lift up, That is, the fuel injector does not inject

fuel; when the solenoid valve is energized, the solenoid valve lifts the

armature by suction. At this time, the fuel in the control chamber

leaks through the ball valve measuring hole, the pressure drops rapidly,

and the pressure in the pressure chamber, as a result, the nozzle

needle valve is lifted, that is, the injector starts to inject fuel;

when the solenoid valve is closed, the pressure in the control room

rises, and the pressure at both ends of the nozzle needle valve is

balanced again, and the nozzle needle valve is under the action of the

spring preload Seated, thereby closing the injector to complete the fuel

injection process.

Working principle of 2.2 high pressure common rail system

The high-pressure fuel output by the fuel pump is accumulated

through a large-volume common rail cavity to eliminate pressure

fluctuations in the fuel and form a constant high-pressure fuel, which

is then distributed to each injector. The opening and closing of the

high-speed electromagnetic switch valve on the injector can regularly

and quantitatively control the amount of fuel injected from the injector

to the combustion chamber of the diesel engine. So as to ensure that

the diesel engine achieves good fuel atomization, the best combustion

ratio, and the best ignition time, sufficient ignition energy and

minimal pollution emissions.

The electronic control unit (ECU)

controls the fuel injection volume of the fuel injector (the fuel

injection volume depends on the fuel rail, public fuel supply pipe),

pressure and the length of the solenoid valve opening time. The basic

control function of ECU is to inject a certain amount of diesel into the

combustion chamber at a set pressure at an appropriate time to ensure

that the diesel engine has high power, low fuel consumption, low

emissions and low noise.

Development of 3. Diesel Engine Electronically Controlled Fuel Injection

The

electronic fuel injection management of diesel engines began in the

1970 s. The development of diesel electronically controlled fuel

injection technology has roughly gone through the following three

generations:

The first generation: position type electronic control

system. The electronic servo mechanism (such as linear solenoid, linear

DC motor) is used instead of the mechanical governor to control the

position of the oil supply rod (in-line pump) or the position of the oil

spill ring (distribution pump) to realize the control of the fuel

injection volume. The electro-hydraulic actuator controlled by the ECU

(electronic control unit) changes the phase between the engine drive

shaft and the camshaft of the fuel injection pump or controls the

movement of the advancer piston to control the fuel injection time. The

first-generation common rail high-pressure pump always maintains the

highest pressure, resulting in waste of fuel and high fuel temperature.

Second

generation: time-based electronic control system. Its structural

feature is that the fuel supply still maintains the traditional pulse

plunger pump fuel supply method, that is, the fuel boost is realized by

the fuel injection pump or the cam of the engine, but the fuel injection

timing (the time when the boost starts) and the fuel injection volume

(The fuel injection volume from the start of the boost to the end of the

boost) is determined by the ECU adjusting the opening and closing time

of the high-speed solenoid valve. Due to the use of high-speed solenoid

valve, its control accuracy has been greatly improved compared with the

first generation. Pre-injection reduces engine noise: a small amount of

fuel is injected into the cylinder for compression ignition within one

millionth of a second before the main injection, preheating the

combustion chamber. The preheated cylinder makes the compression

ignition after the main injection easier, and the pressure and

temperature in the cylinder no longer increase suddenly, which is

beneficial to reduce combustion noise.

Third generation:

time-pressure control system, also known as high-pressure common rail

electronically controlled fuel injection system, with piezoelectric

in-line injectors. It is a brand-new electronically controlled fuel

injection system developed in the mid-1990s. It completely gets rid of

the traditional fuel injection pump and sub-cylinder fuel supply method.

It uses the common rail pressure accumulation and the electronic

control injector of the high-speed solenoid valve actuator. Realize the

comprehensive control of fuel injection pressure, time, fuel injection

volume and various complex fuel injection characteristics. Compared with

the first and second generation electronically controlled fuel

injection systems, it has more obvious advantages.

The fourth

generation diesel common rail electronic control system has been

gradually produced. The fourth-generation common rail electronic control

system of diesel engines is based on the third-generation common rail

system technology to realize free control of fuel injection parameters

such as fuel injection pressure, fuel injection volume, fuel injection

time and fuel injection rate, so that the fuel system The work and the

engine's operating conditions achieve the best match, with comprehensive

control of various additional functions such as exhaust gas

recirculation (EGR), boost control, idle speed control, and cruise

control, it expands the energy-saving technology of "changing

displacement" that has not been adopted by others in the diesel

electronic control system, and the cutting-edge technology of "safety

precautions against sudden braking and wrong stepping on the

accelerator", and integrates "changing displacement", "HCCI", "Three

high-end energy-saving and emission reduction technologies of"

low-temperature plasma exhaust purification. Theoretically, it is

estimated that the fuel saving rate can be increased by nearly 30%, and

the emission of exhaust pollutants can reach or exceed the Euro IV

standard.

Advantages and disadvantages of 4. high pressure common rail system

Advantages of 4.1 high pressure common rail system

The

common rail diesel injection system is different from the previous

cam-driven diesel injection system. It completely separates the

generation of injection pressure and the injection process from each

other, so that the high-pressure common rail system can achieve

functions that cannot be achieved in traditional fuel injection systems.

Its advantages It can be summarized as the following four points:

4.1.1

The injection pressure in the common rail system is flexibly

adjustable, and the optimal injection pressure can be determined for

different working conditions, thereby optimizing the overall performance

of the diesel engine.

4.1.2 It can independently and flexibly

control the fuel injection timing, and with high injection pressure (120

~ 200MPa), it can simultaneously control NOx, particulates and PM2.5

within a smaller value to meet the emission requirements.

4.1.3

Flexible control of fuel injection rate changes, to achieve ideal fuel

injection rules, easy to achieve pre-injection and multiple injection,

can reduce diesel engine NOx, but also to ensure excellent power and

economy.

5. of High Pressure Common Rail Technology at Home and Abroad

1. Research status of domestic high pressure common rail technology

Domestic

research on electronically controlled high-pressure common rail fuel

injection system started late, and most of them are limited to the

research of electronic control unit hardware and other aspects. Only

some universities, enterprises and scientific research institutions

participate in the development of common rail system components. At

present, a mature diesel electronically controlled fuel injection system

has not been developed, and there is still a long way to go before it

is commercialized. The following are the domestic research results in

diesel electronically controlled fuel injection systems: 1) The

electronically controlled in-line pump-pipe-valve-nozzle (PPVI) system

developed by Tsinghua University has developed corresponding

high-performance solenoid valves. 2) The new common rail accumulator

electronically controlled fuel system developed by the State Key

Laboratory of Internal Combustion Engine of Tianjin University is

PAIRCUI in the stage of hardware-in-the-loop simulation and real machine

testing. 3) Zhejiang University conducted a high-pressure common rail

system matching test on the Xichai CA6110 engine. 4) Shanghai Jiaotong

University is in the preparation stage of matching Yuchai YC6110 diesel

engine based on the self-developed GD-1 high-pressure common rail

system. 5) Guangxi Yulin Diesel Engine Factory cooperated with Tsinghua

University to develop a high-pressure common rail injection system for

GDI diesel engines. 6) Wuxi Oil Pump Nozzle Research Institute, in

cooperation with Wuxi Diesel Engine Factory, has successfully tested the

common rail injection system in CA6110 turbocharged and intercooled

diesel engine. 7) Wuxi Weifu Group and Bosch have jointly established

Wuxi Bosch Automotive Diesel Engine Systems Co., Ltd. and started the

production of high-pressure common rail systems.

2. Development status of foreign high-pressure common rail technology

So

far, various countries have developed and produced various diesel

engine electronic control systems, which have effectively alleviated the

current worldwide energy crisis and automobile pollution. Some

automobile industry developed countries diesel engine electronic control

technology level is now quite developed.

At present, 100 per cent of

heavy vehicles and 90 per cent of light vehicles in Europe and the

United States use diesel engines, while the proportion of diesel cars in

the number of cars in Europe exceeds 40 per cent and the proportion of

new car production exceeds 50 per cent. Bosch's conservative forecast

for the Chinese market is that by 2015, the proportion of diesel

vehicles will reach 25%, while by 2015, according to some articles, the

market share of diesel vehicles will increase to about 15% in the field

of light vehicles and cars in the United States.

3. Research direction and problems to be solved of high pressure common rail technology

The

research and development hotspots of common rail technology are as

follows: 1) Numerical simulation technology of fuel injection system.

The numerical model of electronically controlled high pressure common

rail fuel system is established by simulation software, and the

influence of fuel injection process and system parameters on fuel

injection characteristics is analyzed, which provides a theoretical

basis for the optimization design and fault analysis of fuel system.

Reduce product development costs and shorten development cycles. 2)

Solve the problem of uneven fuel injection caused by small fluctuations

in common rail pressure. The dynamic pressure stability of the high

pressure common rail system directly affects the realization of the

ideal injection law of the system. 3) Research on new solenoid valve.

The solenoid valve of the future requires faster response, accuracy,

repetition, reliability and good flow capacity. Such as the use of

piezoelectric ceramic actuator to develop high response solenoid valve.

4) Sensor technology. With the continuous improvement of injection

pressure, new intelligent sensors with higher accuracy and response

speed are required. 5) Research on the optimal control strategy. The

control technology of multiple injection and the regulation of injection

law by controlling pressure.

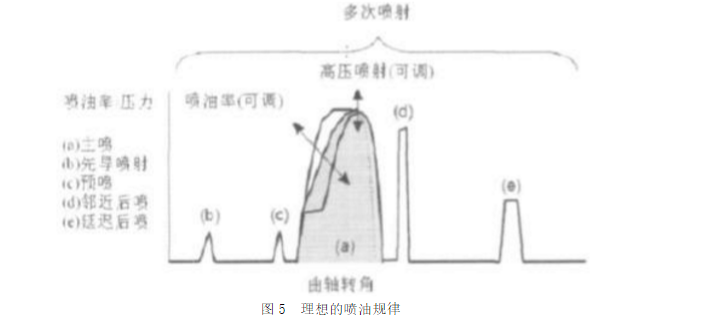

A comprehensive analysis of the history

and current situation of research on diesel electronically controlled

fuel injection systems at home and abroad. The electronically controlled

high pressure common rail system has a lot of room for development.

Mainly to further tap the flexible diversity of electronic control and

common rail system pressure. The potential of the time control

principle. In order to obtain the ideal injection law (Figure 5), the

focus is to increase the injection pressure and improve the flexibility

of the injection rate control. The main technical measures are

multi-stage pressure control and multiple injection.